CFC Charging Systems

NKCG engineering configures solution optimized for the specific

heat treatment process using FEA/CFD and other advanced tools.

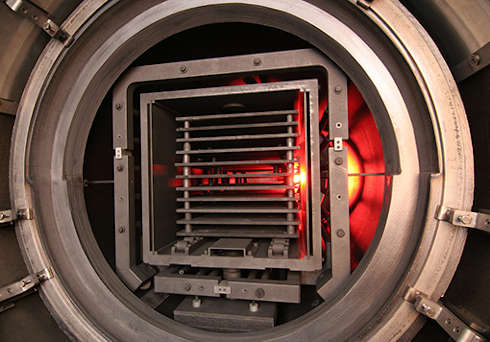

NKCG systems are being used in various applications such as:

Carburizing | LPC | Sintering | PVD/CVD | Vacuum Brazing | Inert gas and vacuum atmospheres

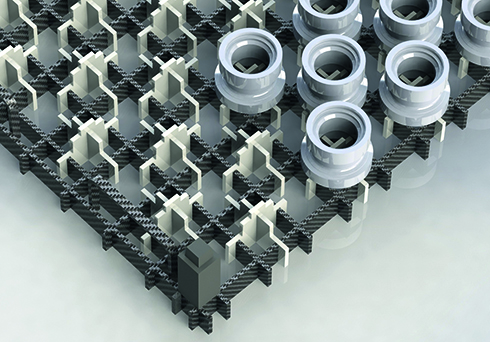

Key advantages of CFC

Low thermal mass allows rapid heat up and cool down

Reduction of energy during each cycle

Increased load capacity

Option to repair spare parts of a rack & recoating

Less weight = less danger due to handling accidents

Mechanical strength increases with temperature

Improving the quality of the treatment result with precision load arrangement

High stability while being resistant to thermal shock (no deformation)

C/C systems are not susceptible to fatigue

Combination of stainless steel based charging plate and CFC load system possible

Custom design for your specific application – optimizes your process

Tool-Box

- CCM-190C (12K 2D CFRC)

- CCM-193C (6K 2D CFRC)

- CCM-190S (Si infiltrated CFRC)

- CCM-400C (Multidirectional CFRC)

- IGS-743 (CIP Graphite)

- GR-133 (Molded Graphite)

- NK-PyC (PyC CVD/CVI Coating)

- NK-PURE (<5ppm Purification)

- BN (Solid or Coating)

- ZrO2 (Coating)

- Al203 (Solid or Plasma Coating)

- Whipox® (2D Al203 Continuous Fiber)

Our Services

- Visit on site in order to evaluate the exisiting system

- 10 questions catalogue - will help to assure all parameters will be detected and clarified

- Customized CFC system to your application

- Retrofit of existing CFC or steel racks

- Coating options in BN, Al2O3, SiC & PyC; purification <5ppm

- Repair and recoating of exisiting and used CFC systems

- Application advice based on our long-term experiences

- Long-term experience in serving aerospace and aviation customers

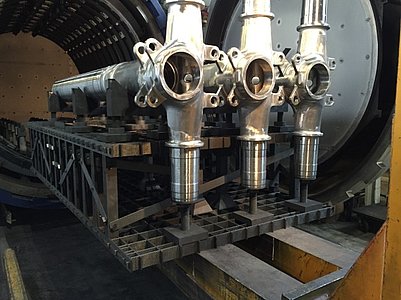

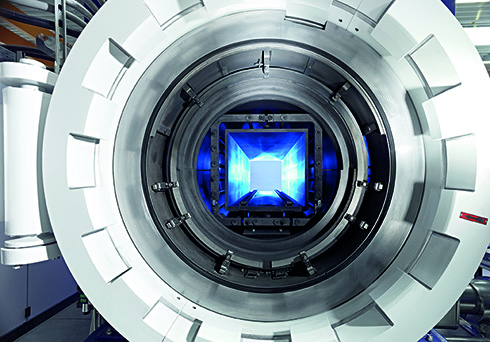

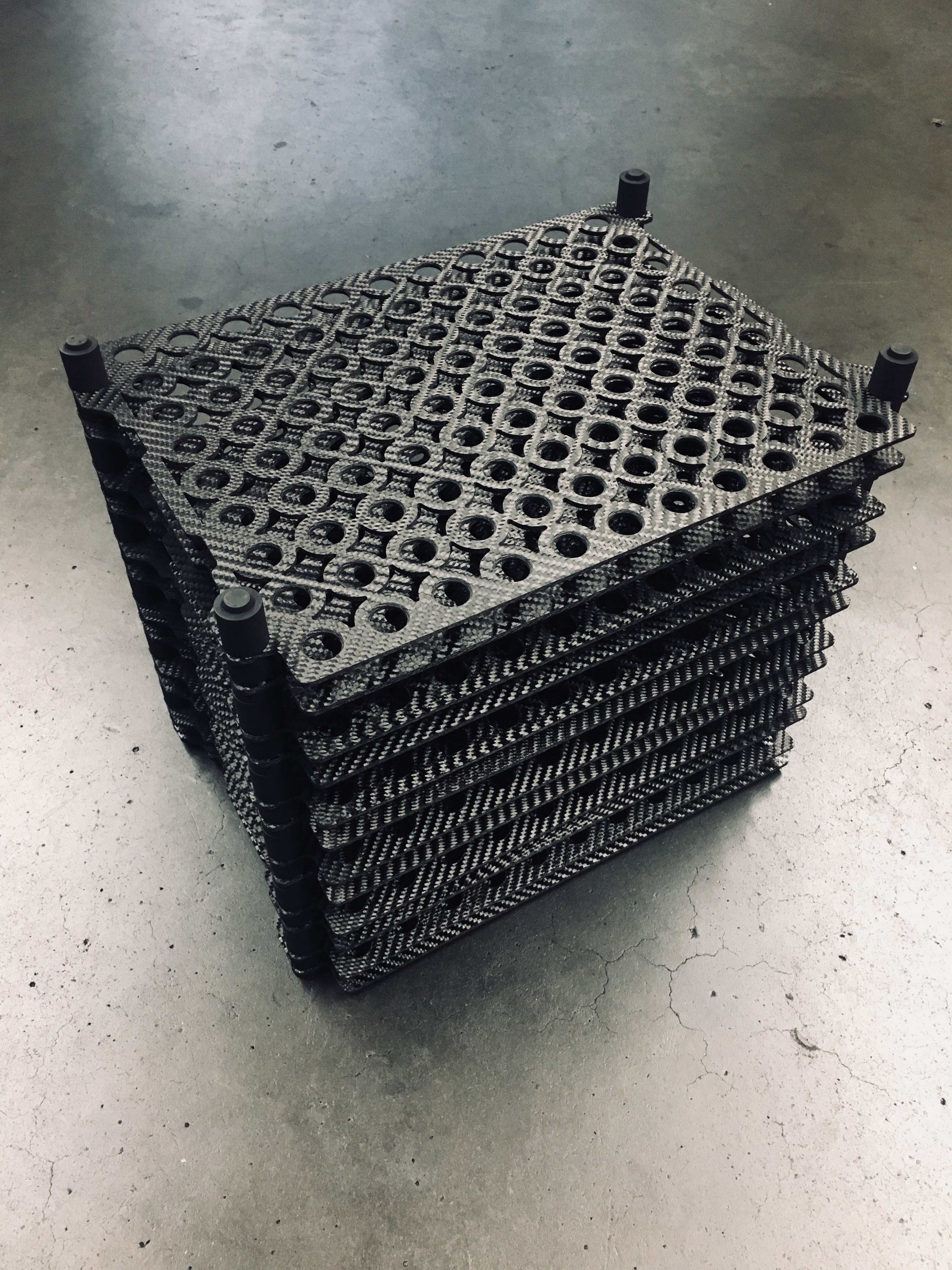

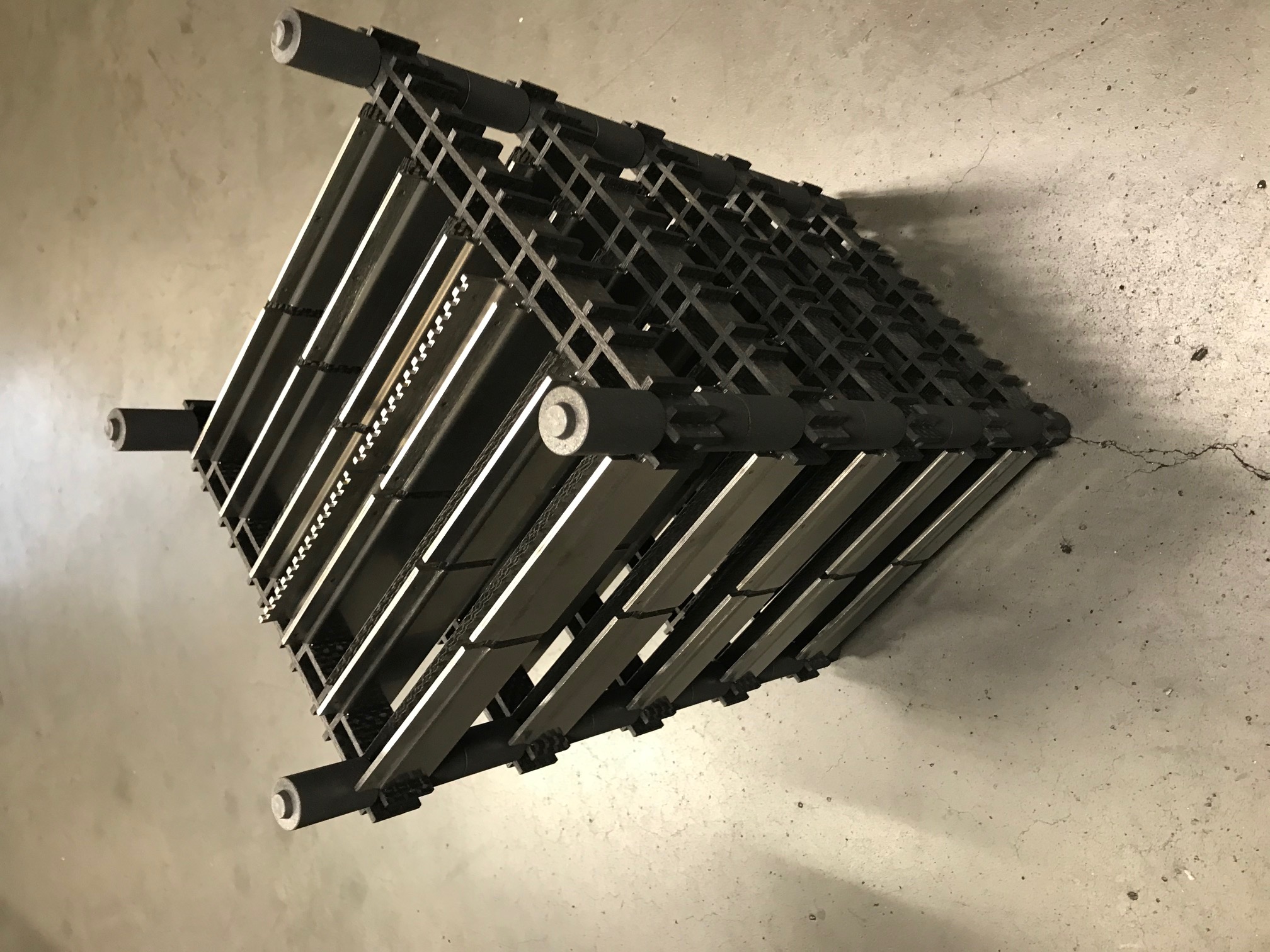

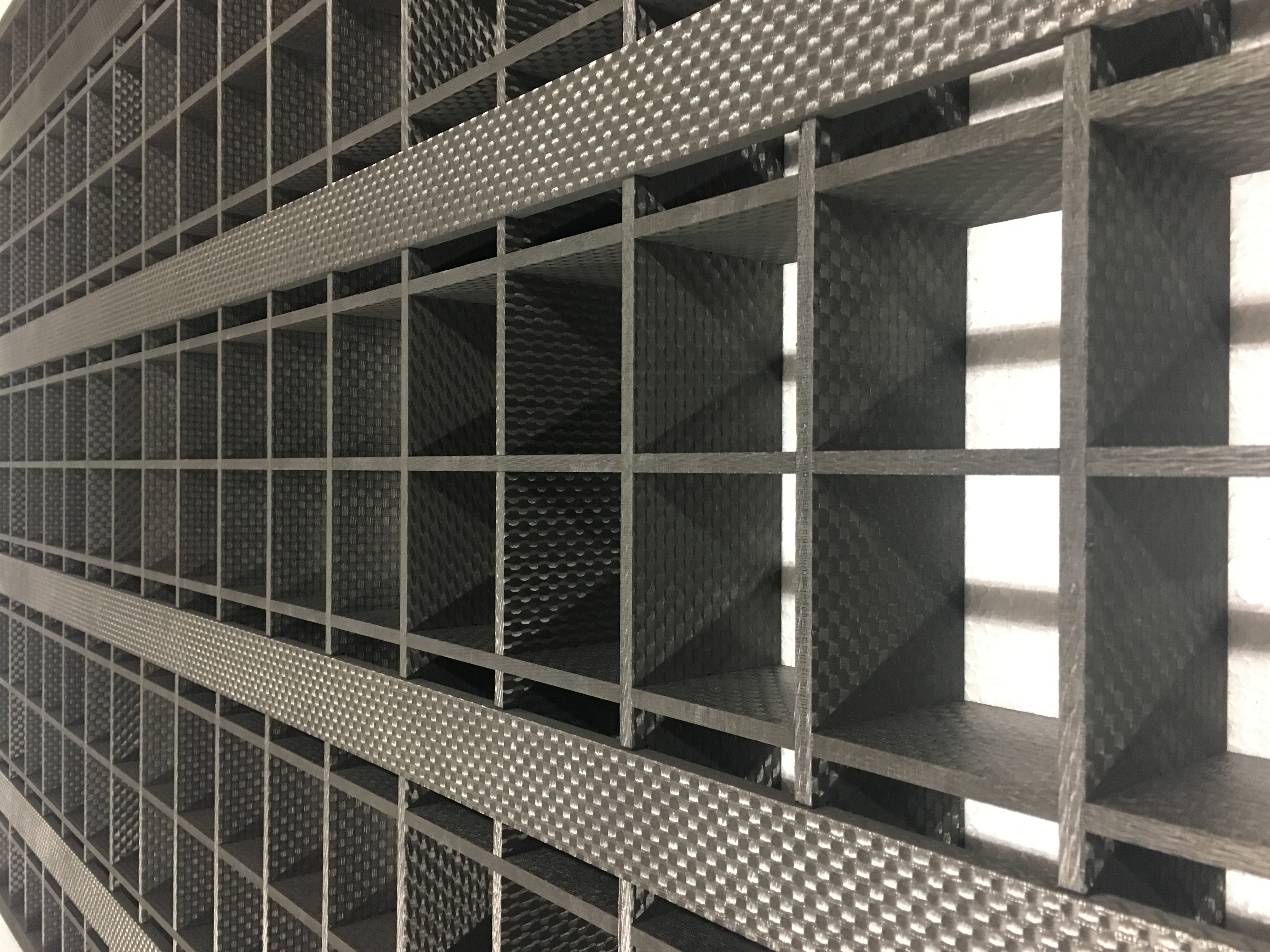

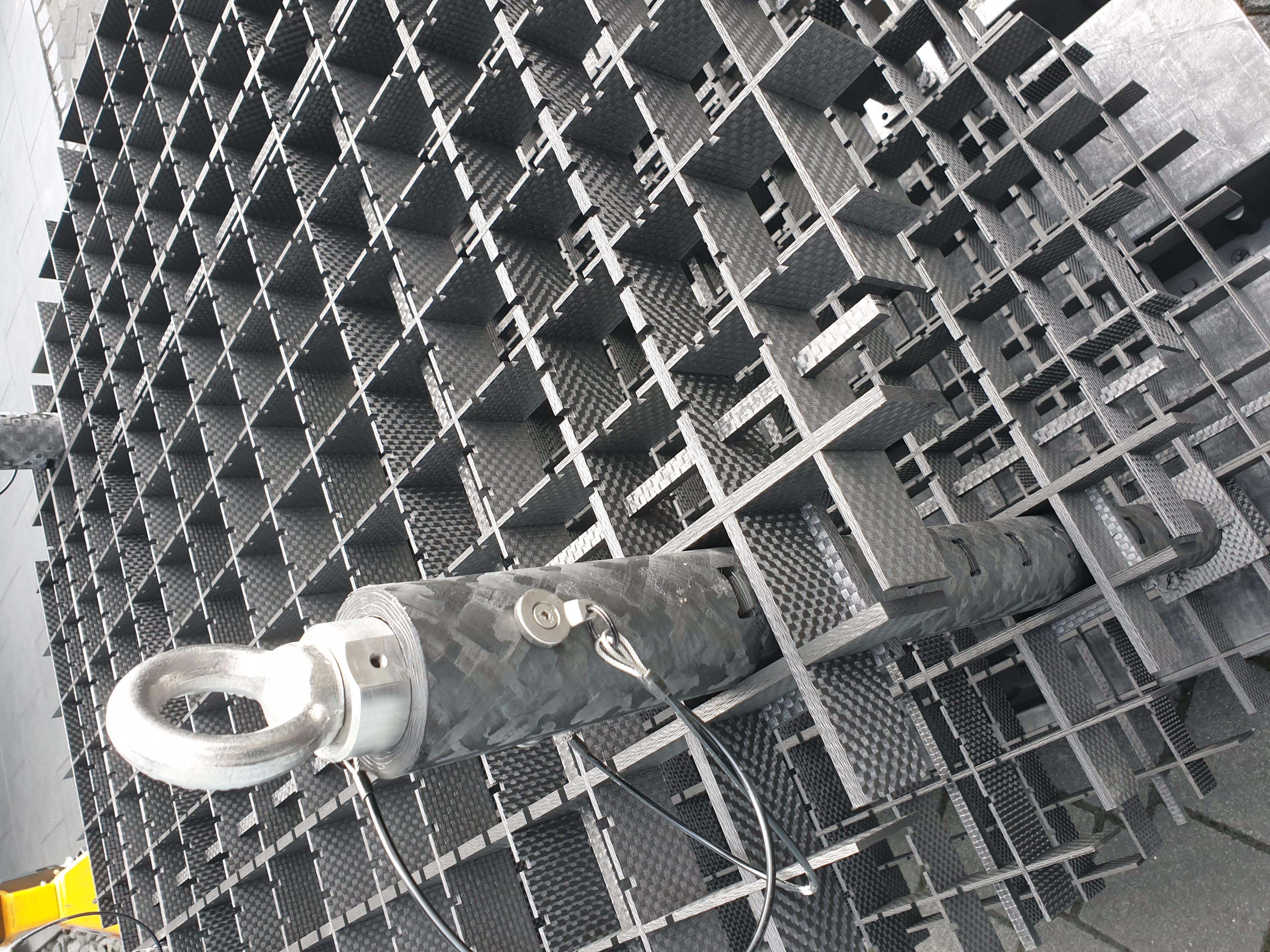

Gallery

Several examples of CFC Charging Systems